This consolidates overhead cost information from multiple sources, including payroll, point-of-sale, billing and predetermined overhead rate more. With a unified data set, generating financial statements and calculating accurate overhead rates is streamlined. This $4 per DLH rate would then be used to apply overhead to production in the accounting period. The difference between actual and applied overhead is later assessed to determine over- or under-application of overhead. The key is choosing an appropriate cost driver – like machine hours in manufacturing or headcount in sales – to distribute overhead expenses.

Multiple or departmental predetermined overhead rates:

The predetermined rate is a calculation used to determine the estimated overhead costs for each job during a specific time period. Predetermined overhead rates are also used in the budgeting process of a business. As discussed above, a business must wait until the end of a period to know the actual performance in terms of overheads incurred. However, since budgets are made at the start of the period, they do not allow the business to use actual results for planning or forecasting. Therefore, the business must use a predetermined overhead rate to budget its expenses for the future. When multiple departments or divisions within a company operate as separate profit centers, predetermined overhead rates facilitate the allocation of shared costs.

Practical Examples: Simplify Cost Estimation with Real-World Scenarios

A predetermined overhead rate is often an annual rate used to assign or allocate indirect manufacturing costs to the goods it produces. Manufacturing overhead is allocated to products for various reasons including compliance with U.S. accounting principles and income tax regulations. Larger organizations may employ a different predetermined overhead rate in each production department, which tends to improve the accuracy of overhead application by employing a higher level of precision. However, the use of multiple predetermined overhead rates also increases the amount of required accounting labor.

Setting pricing

- As previously mentioned, the predetermined overhead rate is a way of estimating the costs that will be incurred throughout the manufacturing process.

- Take, for instance, a manufacturing company that produces gadgets; the production process of the gadgets would require raw material inputs and direct labor.

- Activity-based costing (ABC) is a more complex but accurate method of assigning overhead costs based on the activities consumed in the production process.

- In order to calculate the predetermined overhead rate for the coming period, the total manufacturing costs of $400,000 is divided by the estimated 20,000 direct labor hours.

- However, for most businesses waiting until the product has been produced to determine its costs may not be an option.

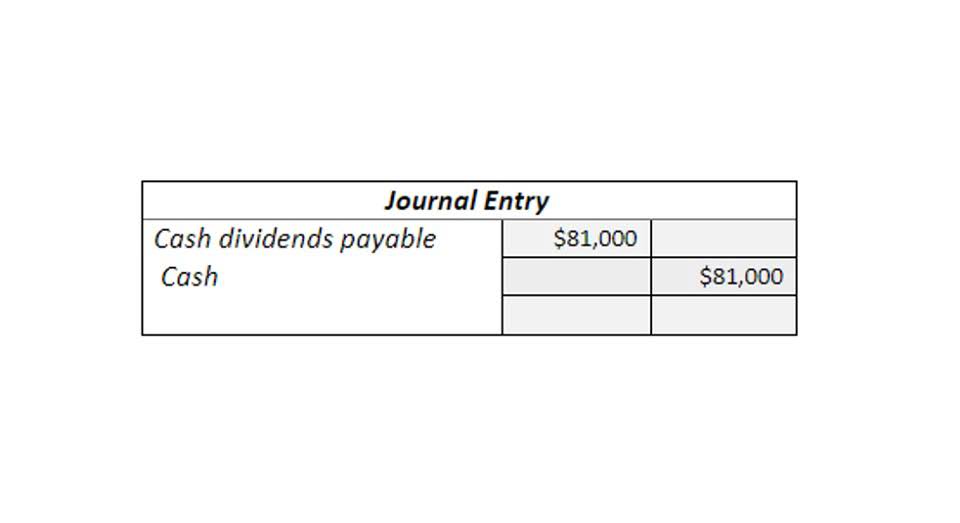

It would involve calculating a known cost (like Labor cost) and then applying an overhead rate (which was predetermined) to this to project an unknown cost (which is the overhead amount). The formula for calculating Predetermined Overhead Rate is represented as follows. The predetermined overhead rate also allows businesses to easily calculate their profitability during the period without waiting for the actual results of its operations. This means that businesses can use the predetermined overhead rate to constantly evaluate its operations without having to wait for actual results to come in. This allows the business to proactively control its performance rather than taking a reactive approach towards it. The choice of selecting any absorption basis depends on the judgment and common sense; especially depends on the type of the manufacturing activities.

How to Label a Package for Shipping: Step-by-Step Instructions with Examples

This allocation process depends on the use of a cost driver, which drives the production activity’s cost. Examples can include labor hours incurred, labor costs paid, amounts of materials used in production, units produced, or any other activity that has a cause-and-effect relationship with incurred costs. For example, the total direct labor hours estimated for the solo product is 350,000 direct labor hours. With $2.00 of overhead per direct hour, the Solo product is estimated to have $700,000 of overhead applied. When the $700,000 of overhead applied is divided by the estimated production of 140,000 units of the Solo product, the estimated overhead per product for the Solo product is $5.00 per unit. The computation of the overhead cost per unit for all of the products is shown in Figure 6.4.

As a result, two identical jobs, one completed in the winter and one completed in the spring, would be assigned different manufacturing overhead costs. To avoid such fluctuations, actual overhead rates could be computed on an annual or less-frequent basis. However, if the overhead rate is computed annually based on the actual costs and activity for the year, the manufacturing overhead assigned to any particular job would not be known until Remote Bookkeeping the end of the year. For example, the cost of Job 2B47 at Yost Precision Machining would not be known until the end of the year, even though the job will be completed and shipped to the customer in March.

Molding Department

- Before jumping to detail, let’s go through the basic overview and key definition first.

- Based on the manufacturing process, it is also easy to determine the direct labor cost.

- Since they can’t just arbitrarily calculate these costs, they must use a rate.

- As a result, management would likely view labor hours as the activity base when applying overhead costs.

- The rate is calculated based on the assumption, and mostly there is small material that we could not avoid.

Table 9.2 illustrates the various cost pools along with their activities and related costs. We’ll outline the basic formulas used to calculate different types of overhead rates and retained earnings provide overhead cost examples. So, base on this formula, you need to know expected annual manufacturing overhead expenses.

Calculation of Predetermined Overhead and Total Cost under Traditional Allocation

Suppose the budgeted cost of overheads for the departmental store amounts to $20,000 per month, and the budgeted level of production is 10,000 per month. The predetermined rate of overheads can be calculated by putting the values in the above formula. The most prominent concern of this rate is that it is not realistic being that it is based on estimates.